Environment / Quality management

Quality control structure pursuing the reassurance and satisfaction of customers

We have acquired the international specification ISO 9001 certification (Note 1 & 2) together with cosmetic GMP standard in year 2004 and established a system that can provide customers with reassurance and satisfaction thorough quality and advanced traceability of cosmetics GMP standards.(Note 1): ISO scope of application: OEM manufacturing of cosmetics and quasi-drugs (Note 2) : Applicable offices: Head office factory and logistic center

Acceptance inspection of raw ingredients・materials

Acceptance inspection of raw ingredients・materials

We organize quality control system that is always stable and conduct according to the receival inspection process determined by the quality management regulation and to be flexible at the same time not to mention but for purchased raw ingredients by our company but also for the acceptance inspection of raw ingredients supplied from the customers side.

Equipment management

Equipment management

It is essential for us to maintain the quality to strictly daily control the delivery date that will satisfy the customers since various equipment used for production, filling and packaging are working inside the production factory. Equipment will maneuver properly by human maintenance and completely demonstrates the original ability. Those management is a means to prevent the unexpected circumstance such as sudden stop of production due to lack of maintenance and is the best ways to strictly keep the promise of the quality and the delivery date. The love towards the equipment will be instantly felt at a glance when maintenance by the workers with knowledge. Our company is a professional group able to properly maneuver the equipment any time by judging the situation of our equipment using the human sight, ,hearing, touching and olfactory.

Hygiene management

Hygiene management

It is essential for us to maintain the clean environment not only for the facility in order to create “uncontaminated product”. In order to do that hygienic management system and pursuing the continuous improvement of the environment and to follow the determined rule. This requires a backed hygiene management system, continuous environmental improvement, and adhering to established rules. Creation of environment for manufacturing section, under the management division of quality・environment, Maintaining high cleanability by conducting repeated precise treatment and improvements by various monitoring tests such as “Environmental microorganism test”, “Floor rinsing confirmation test” and “Facility・equipment adhered bacteria test” that are segregated by rinsing regulation according to the work place to maintain high cleanability. Also, rinsing is managed by “Procedure for rinsing and sterilization“ according to each equipment and always been rinsed and sterilized according to this determined procedure. These procedures are backed up by the “Rinsing・sterilization process confirmation test” There are precise regulations for entering the workplace since most of the contamination of workplace is confirmed due to human aspects. Permission to the room will be allowed after passing various phases such as “Wearing the determined clothes”, ”Adhesive sheet” “Air shower (Doubled door interlock)”, ”Procedure for sterilized hand wash” etc. Also other than the management to prevent pollutants such as bacteria and dust from entering, we determine the “Limitation for bring in and quantity” of the stationary used in workplace and by following strictly to these rules, we prevent pollutants and foreign materials from entering inside the room.

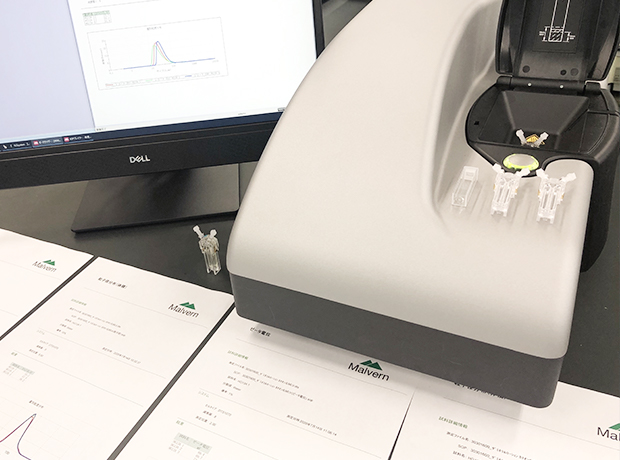

Bulk・Semi-finished product inspection

Bulk・Semi-finished product inspection

Test is regulated inside ”Bacteria test method”, “Bulk test procedure”, and “semi-finished product checking procedure” with total of 18 testing items are determined such as pH, specific gravity, viscosity, quantity of effective ingredients by high performance liquid chromatography and measurement of bulk particles that is being nanosized and being conducted to control the stability of bulk. Also, we make sure to confirm the quality by implementing “sensory test(Confirmation of texture)” for all the products by determining the testing method according to the actual use since “cosmetics gets direct contact with the skin”.

Improvement process

Improvement process

All regulation must always be pursuing for continuous improvements by strictly adhering to high quality with a system that conducts internal and external audits and thoroughly and rigorously checking for deviations from the regulations.